It is a high-power neutron spallation source which is being created by 40+ in-kind contributors from around the world. One of several in-kind work packages that Technology at Daresbury Laboratory undertook, on behalf of the UK, was the production of beam transport modules (BTMs), sometimes called linac warm units (LWUs).

Main components of the BTM

Main components of the BTM

.

What is a beam transport module?

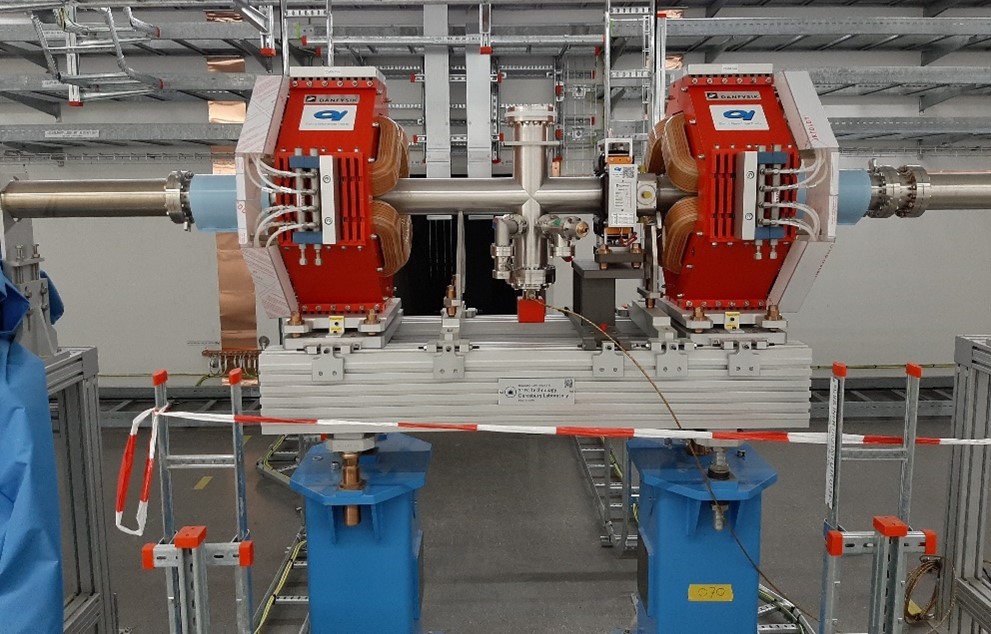

The ESS uses nuclear spallation, a process in which neutrons are liberated from heavy elements by high-energy protons. 74 BTMs are positioned along the 600-metre accelerator line to help control and direct the protons onto the heavy tungsten target at the end. The modules comprise of UHV (ultra-high vacuum) chambers, diagnostics, magnets, and a highly stable mounting system.

A BTM installed at the ESS

.

Who was involved?

Technology at Daresbury Laboratory successfully designed, cleaned, assembled, tested, and delivered 74 of these modules to Sweden, along with 52 UHV dummy cryomodules. When the BTMs are coupled to the dummy cryomodules, the complete system measures 480m and makes up 80% of the total accelerator length.

The Technology's teams involved from Daresbury Laboratory include:

-

Project and Mechanical Engineering Group – providing project management, mechanical design, analysis, and onsite support.

-

Mechanical, Metrology and Technical Engineering Group – providing assembly, low particulate cleaning in ISO 3 cleanroom, survey and alignment.

-

Electrical Engineering Group – providing installation and testing.