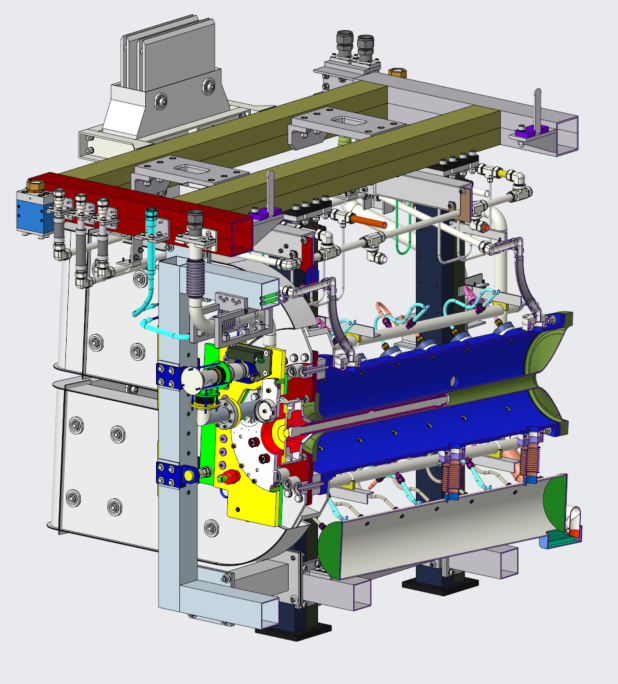

Sectional model of the horn and target assembly T2K is a world-leading particle physics experiment which studies the nature of neutrino oscillations – a phenomenon which occurs when neutrinos that have one ‘flavour’ (electron, muon, or tau) are later measured to have another.

Sectional model of the horn and target assembly T2K is a world-leading particle physics experiment which studies the nature of neutrino oscillations – a phenomenon which occurs when neutrinos that have one ‘flavour’ (electron, muon, or tau) are later measured to have another.

The experiment works by sending an intense beam of muon neutrinos from the J-PARC facility in Tokai 295km to the SuperKamiokande (SuperK) far detector in Kamioka.

To produce the neutrino beam, the facility collides protons with a graphite target . These collisions generate pions which are then focused into a beam using a magnetic horn and rapidly disintegrate to produce the muon neutrinos the experiment requires .

This graphite target, along with a target exchange mechanism, beam window, collimator, and beam dump, is the responsibility of the Technology Department’s High-Power Targets Team at the Rutherford Appleton Laboratory (RAL).

From Beam Dumps to High-Power Graphite Targets

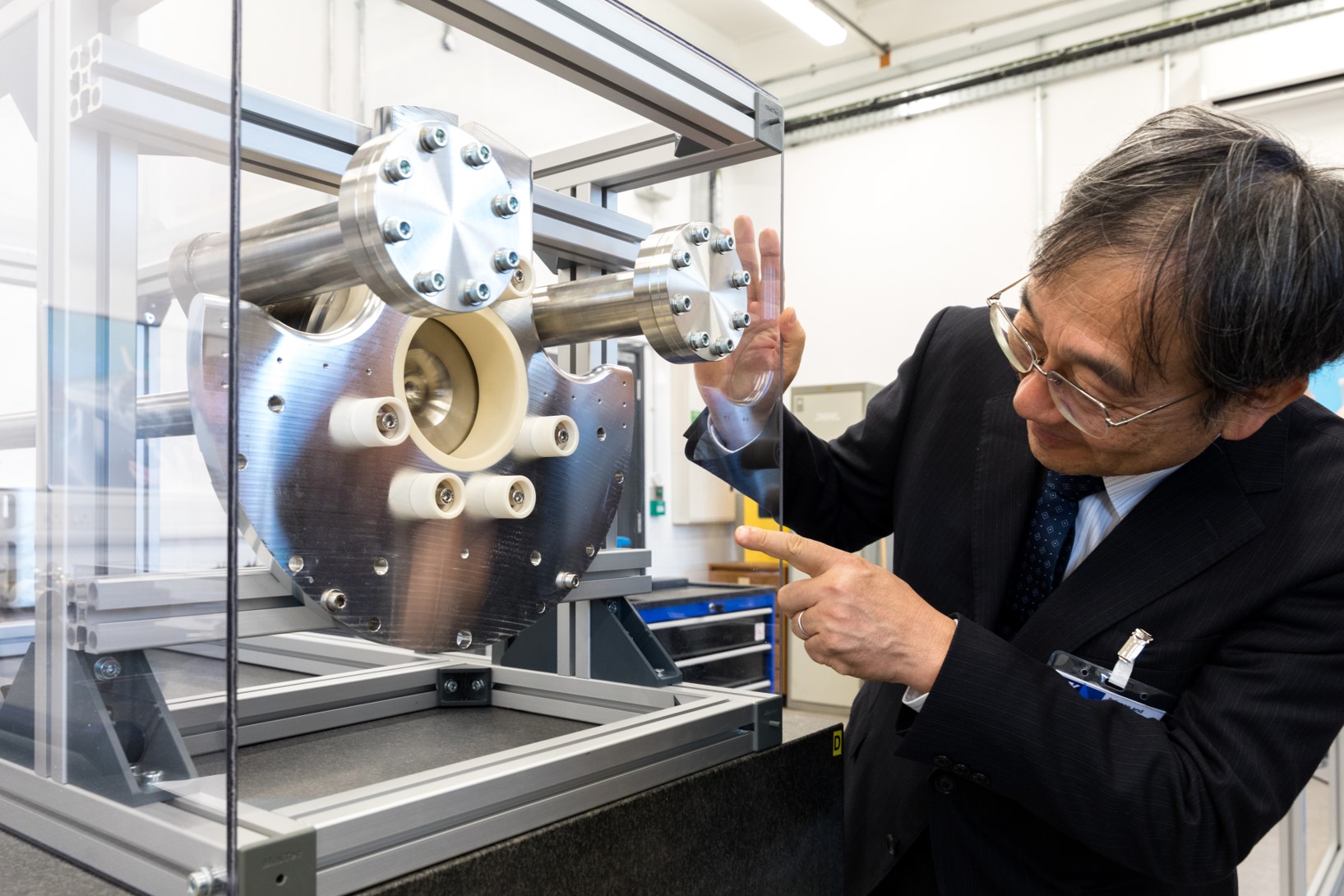

Eric (centre, a member of the High-Power Targets team) providing

Professor David Wark (left, PI for T2K-UK and HyperK-UK) and

Professor Nakahata Masayuki (right, SuperK spokesperson) a tour

of the team's target lab.

The RAL collaboration with KEK (Japan’s High Energy Accelerator Research Organisation) on the T2K project began approximately 20 years ago – with an initial invitation from Professor Dave Wark, the first international co-spokesperson of the experiment and previous director of STFC’s Particle Physics Department.

Starting with the design of the beam dump, a series of large graphite blocks which absorb the remnants of the experiment’s proton beam and safely dissipate its energy, the team’s responsibilities soon expanded to include several beamline components (in addition to the neutrino target itself).

These components include:

-

Target exchange mechanism – a remote system that allows the highly radioactive targets to be safely and quickly replaced (although no targets have failed in operation yet).

-

Vacuum-to-gas beam window – through which the proton beam passes from the accelerator vacuum into the target station.

-

Collimator/baffle – which protects components from the potential damage caused by a mis-steered proton beam.

With these components in place, T2K began operation in 2010 (interrupted for a year by the Great Tohoku Earthquake) and soon enabled scientists to make the first accelerator measurements of the last neutrino mixing angle (θ13).

The data collected since has provided hints that neutrinos and their anti-matter equivalent behave differently, something which is not explained by our standard model of particle physics.

After several facility upgrades, on Christmas Day 2023, the experiment achieved stable operation at the original design proton beam power of 750kW.

Further upgrades are planned to achieve an ultimate beam power of 1.3MW in time for the installation and operation of the experiment’s new far detector – Hyper Kamiokande (HyperK).

Scientists at T2K anticipate that this beam power, in combination with the new detector, will provide enough data to make a definitive measurement of the difference between matter and antimatter particles.

In anticipation of this upgrade, RAL’s High-Power Targets Team have already completed the design and manufacture of the first 1.3MW target.

How do you develop the perfect neutrino target?

Professor Nakahata Masayuki inspecting the first 1.3 MW capable neutrino production target recently manufactured at RAL.The T2K neutrino target comprises an almost 1m-long core of nuclear-grade graphite, cooled by high-velocity gaseous helium contained within a titanium alloy vessel.

Professor Nakahata Masayuki inspecting the first 1.3 MW capable neutrino production target recently manufactured at RAL.The T2K neutrino target comprises an almost 1m-long core of nuclear-grade graphite, cooled by high-velocity gaseous helium contained within a titanium alloy vessel.

Built to withstand an intense pulsed proton beam generating thermal shocks and radiation damage, the atoms within the target’s titanium beam window will be displaced two to three times in a year of operation (a phenomenon which is measured using DPA or displacements-per-atom).

Developing a target which could withstand these extreme conditions involved considerable testing using analysis software such as FLUKA and Ansys CFX.

These simulations included Finite Element Analysis (used for predicting how the component will be affected by forces, vibrations, or heat) and Computational Fluid Dynamics (utilised to analyse the flow and interaction of the helium gas that cools the target).

Technology staff involved in the project carefully selected the target materials for their ability to withstand radiation damage, designed for extreme environments, and selected and tested joints and metal seals capable of withstanding intense fluctuations in heat.

Support was also provided by the department’s Manufacturing Facilities team, which was responsible for manufacturing the target’s thin-walled, complex titanium parts.

Collaborator of Choice

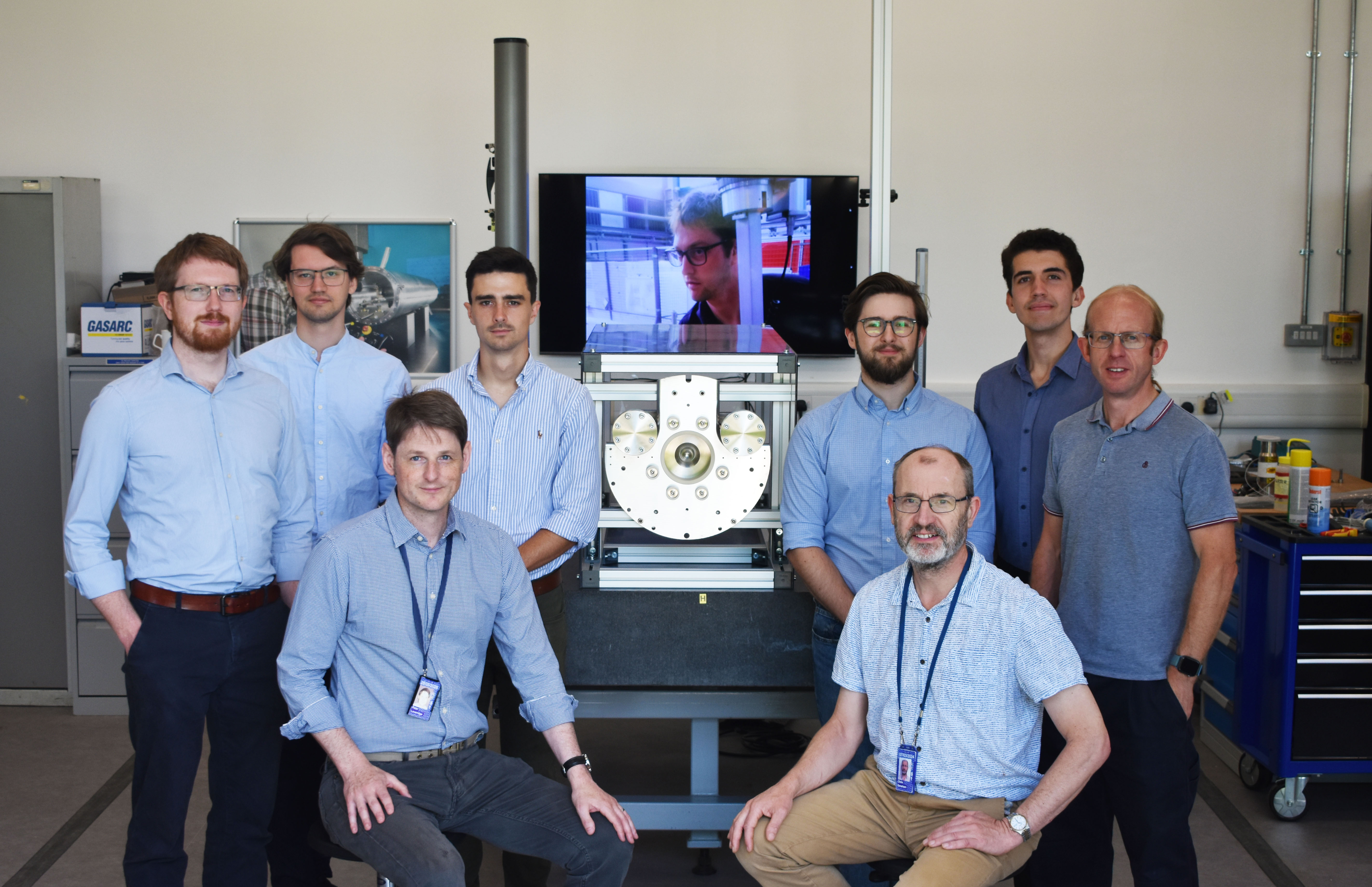

A photo of the High-Power Targets team (taken last year).The Technology Department’s High-Power Target Team has positioned itself as a collaborator of choice for several international accelerator facilities including T2K and its counterpart in the US, the Long-Baseline Neutrino Facility (LBNF).

A photo of the High-Power Targets team (taken last year).The Technology Department’s High-Power Target Team has positioned itself as a collaborator of choice for several international accelerator facilities including T2K and its counterpart in the US, the Long-Baseline Neutrino Facility (LBNF).

Dr Chris Densham, High Power Target Group Leader, discussed how his team approaches this unique challenge:

“The highly demanding requirements of particle physics projects such as T2K have provided the opportunity for us to showcase some of the design, engineering, and manufacturing capabilities here at STFC. Maintaining this engagement over many years has opened the door for us to carry out similar roles for experiments which compete at the scientific level, but where we work in strong collaboration with international colleagues at a technical level.

“Not being tied to any one facility permits us to develop our knowledge of specialist techniques in a variety of interesting projects and then apply this experience to similar challenges we may find at completely different facilities."

Written by Cat Lewin-Williams